Cooling Heating DC Motor Fan Coil Unit Ceiling Fan Coil

1. Ceiling exposed floor standing DC fan coil types

Four style universal fan coil unit can be selected:

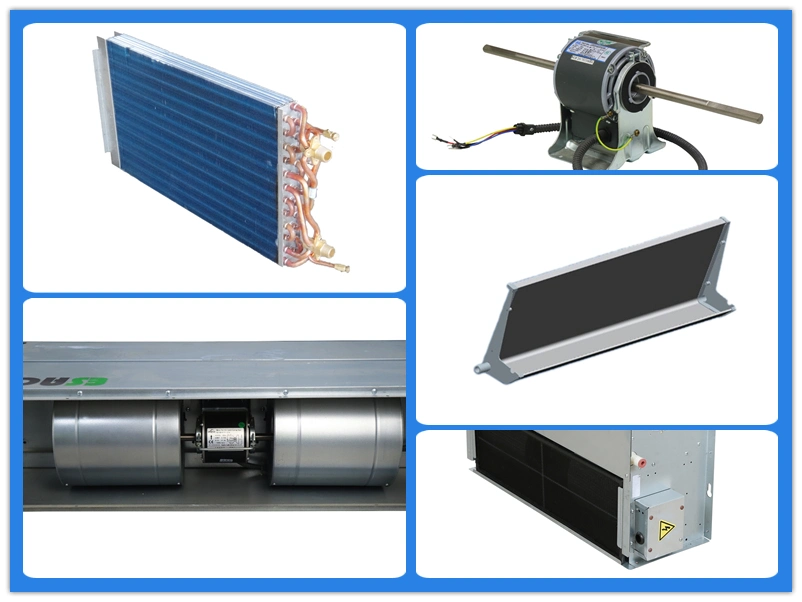

2. DC Ceiling exposed fan coil unit main components

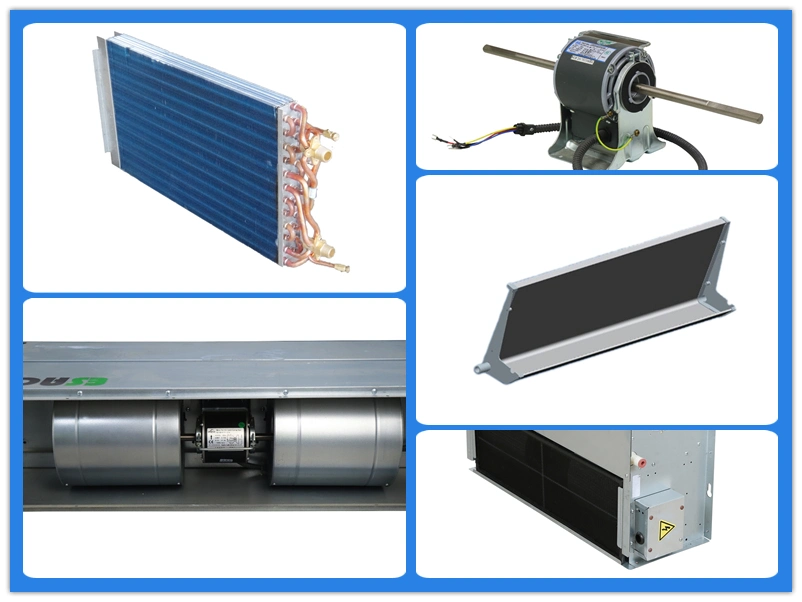

(1) Fan

Fans are double inlets multi-blade centrifugal type. All fans are statically and dynamically balanced.

(2) Motor

Direct current Brushless single-phase motors are suitable for different voltages, such as 110V, 115V, 120V, 220V, 230V, 240V. All motors have 10 percent voltage utilization range and wired to unit terminal box. Motors are designed for long life.

(3) Drain pan

Drain tray is made of plastic with hollow inside L shape and cover the entire coil.

(4) Water coil

Coils are standard design together with rows. High efficient hydrophilic aluminum fins are mechanically bonded to seamless copper tubes. All coils are specifically designed and circuited for water use. All coils are tested at 3.3MPa.

(5) Casing

Casing are constructed of heavy gauge steel. Air outlet grille and return air grille is ABS material for easy maintenance.

Units are furnished as standard with a 1 inch duct collar to facilitate connection of the supply air duct.

(6) Return air plenum

The fan coil unit shall be factory installed return air plenum that encloses the fan section of the unit. No field fabrication is required. The return air arrangement is adaptable between bottom or front return of the plenum.

(7) Washable filter

Filter should be accessible from return air grille.

3. Ceiling exposed floor standing DC fan coil features

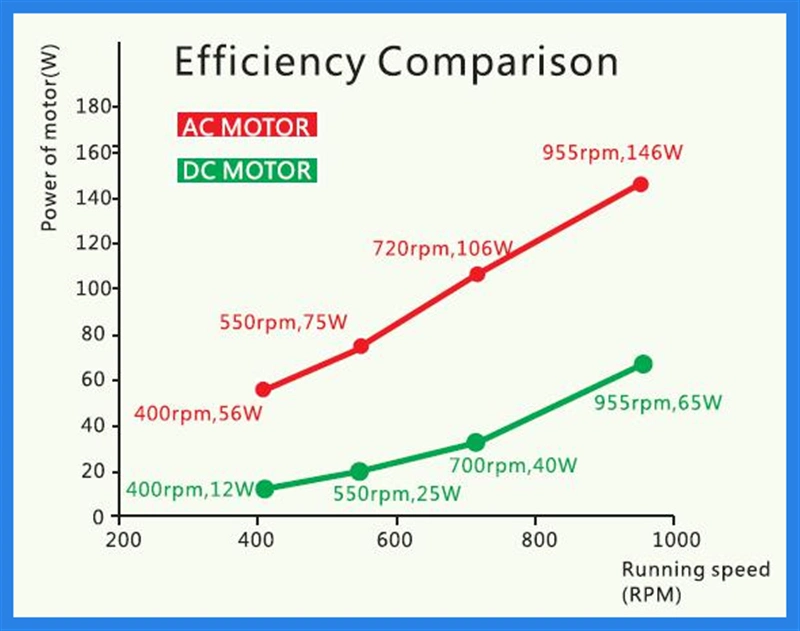

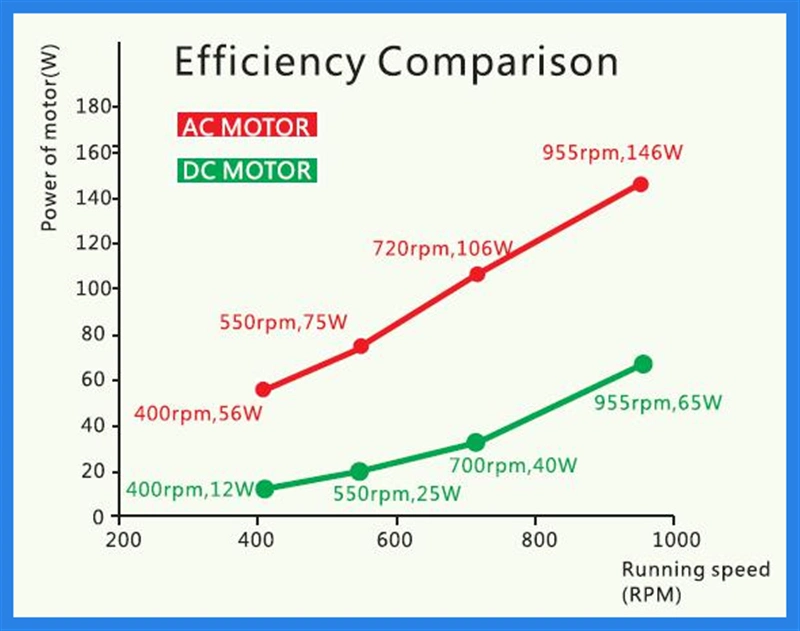

(1)Adopt famous branded high quality BLDC motor,high efficiency and low energy consumption;DC motor energy consumption is average less than 60% of AC motor.

(2)With long running life: as common AC motor is low operating efficiency,usually only 40~45% power consumption turn into kinetic energy,that means balance 55~60% energy is converted into heat,this heat may cause aging to motor components,which is harm to the motor life.DC brushless motor efficiency is always more than 80~95%,so only little energy changes to heat to prevent motor aging.

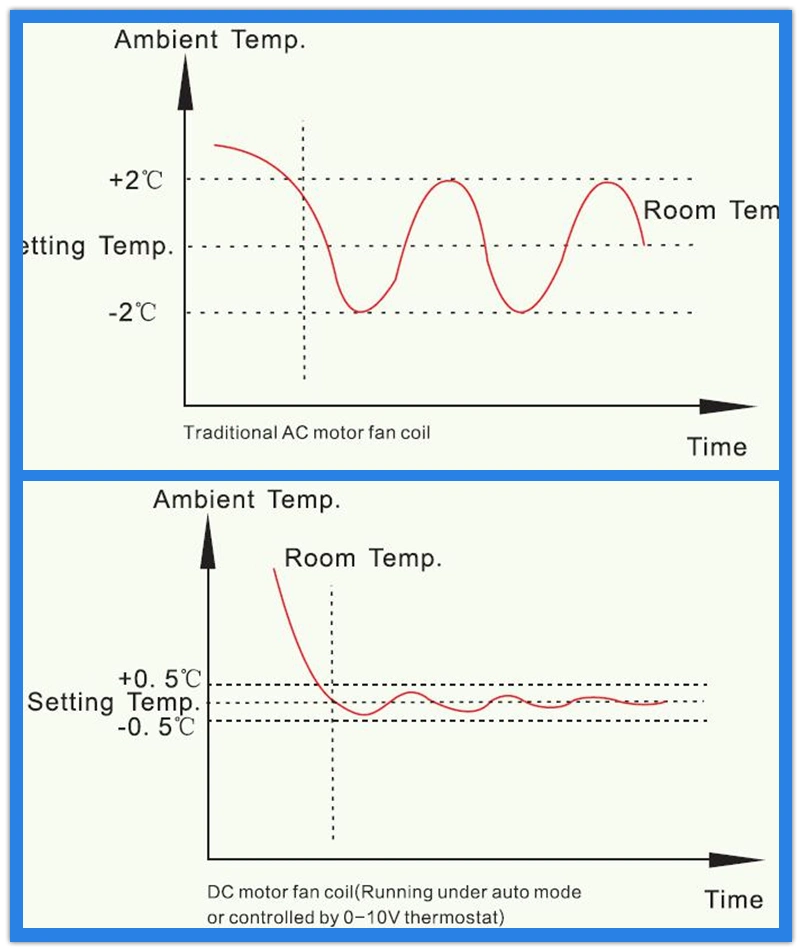

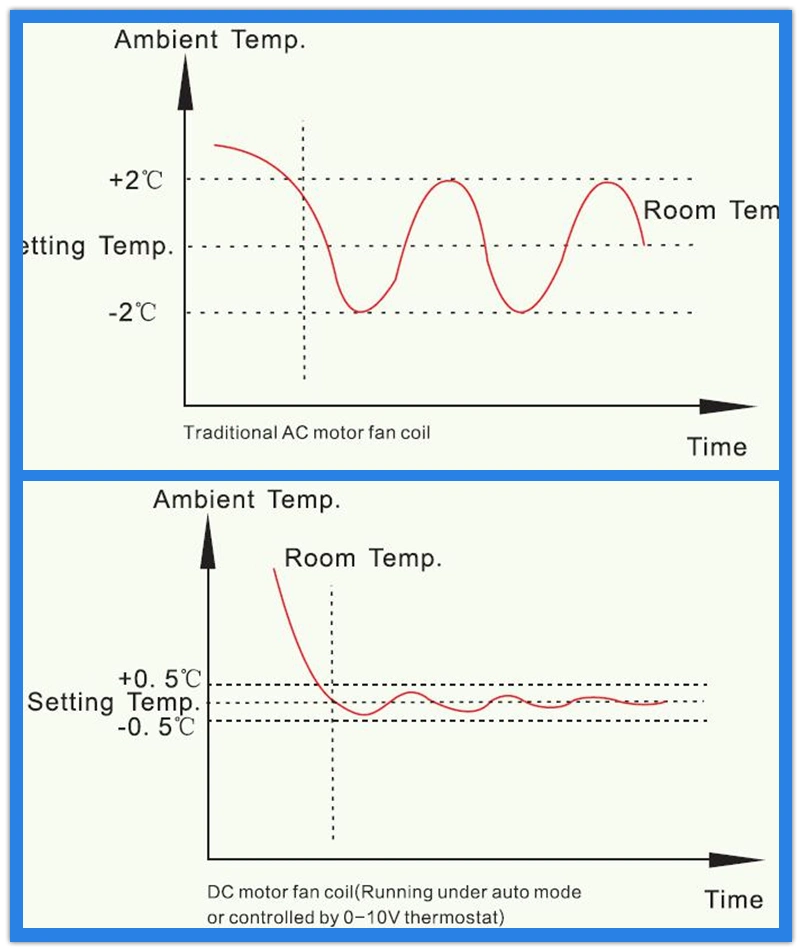

(3)Fast cooling/heating,temperature fluctuation is small,more comfortable.

a. If temperature difference between room temperature and setting temperature is big:

for normal AC style FCU,the fan will run under the setting speed;while the DC style will automatically run at high speed to make the room temperature to the setting temperature.

b. When the room temperature reach the setting temperature,the AC style fan coil will stop the fan running or close the water valve,this will cause the cooling/heating can not continue and there is temperature shock in the room;while the DC style fan coil will change its running speed according to the temperature difference between room temperature and setting temperature:if the distance is big, the fan speed will be higher,and if the distance is smaller ,the fan speed will be lower.

5. Ceiling floor standing exposed fan coil unit specification (DC motor)

Please ask salesman for detailed complete data or visit our website:

eurostarschiller.en.made-in-china.com

eurostarschiller.en.made-in-china.com

Remarks:

(1) Cooling: Inlet air temperature DB 27ºC,WB 19.5ºC; Chilled water inlet/outlet temp. 7ºC/12ºC.

(2) Heating: Inlet air temperature DB 20°C, heating water inlet/outlet temperature 60°C/50ºC.

(2) Professional team with over more than 10 years industry knowledge

(3) Oversea installation.

(4) Customer-made accepted.

(5) Diamond member of Made-In-China

(6) Audited supplier by SGS

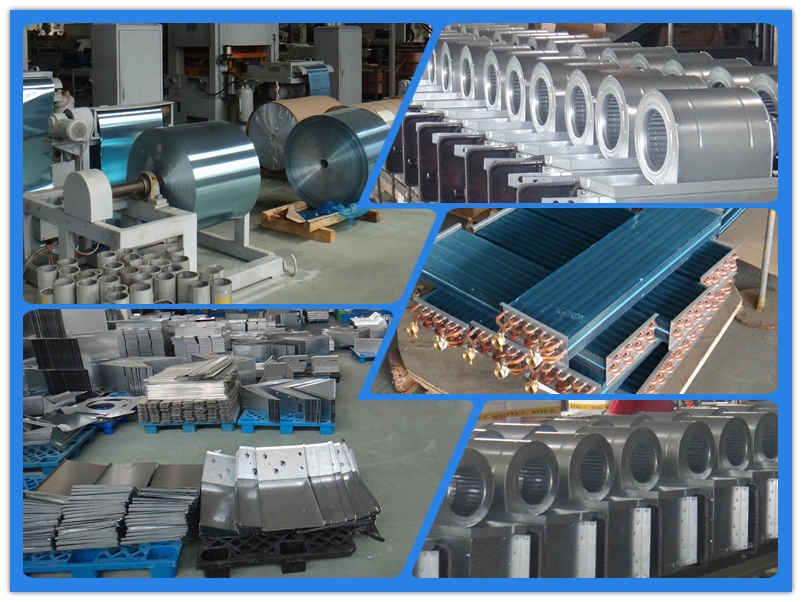

7. Our fan coil production line

Every fan coil has strict production process, including assembly, testing, packing.

8. Our service and Customer visit

Economical and energy-saving design scheme

Overseas engineer services

Integrated quality and profession R&D team

OEM/ODM available

1. Ceiling exposed floor standing DC fan coil types

Four style universal fan coil unit can be selected:

| Horizontal ceiling type with air return from downward without supporting legs |

| Floor standing type with air return from front with supporting legs |

| Horizontal ceiling type with air return from backward without supporting legs |

| Floor standing type with air return from bottom with supporting legs |

2. DC Ceiling exposed fan coil unit main components

(1) Fan

Fans are double inlets multi-blade centrifugal type. All fans are statically and dynamically balanced.

(2) Motor

Direct current Brushless single-phase motors are suitable for different voltages, such as 110V, 115V, 120V, 220V, 230V, 240V. All motors have 10 percent voltage utilization range and wired to unit terminal box. Motors are designed for long life.

(3) Drain pan

Drain tray is made of plastic with hollow inside L shape and cover the entire coil.

(4) Water coil

Coils are standard design together with rows. High efficient hydrophilic aluminum fins are mechanically bonded to seamless copper tubes. All coils are specifically designed and circuited for water use. All coils are tested at 3.3MPa.

(5) Casing

Casing are constructed of heavy gauge steel. Air outlet grille and return air grille is ABS material for easy maintenance.

Units are furnished as standard with a 1 inch duct collar to facilitate connection of the supply air duct.

(6) Return air plenum

The fan coil unit shall be factory installed return air plenum that encloses the fan section of the unit. No field fabrication is required. The return air arrangement is adaptable between bottom or front return of the plenum.

(7) Washable filter

Filter should be accessible from return air grille.

3. Ceiling exposed floor standing DC fan coil features

(1)Adopt famous branded high quality BLDC motor,high efficiency and low energy consumption;DC motor energy consumption is average less than 60% of AC motor.

(2)With long running life: as common AC motor is low operating efficiency,usually only 40~45% power consumption turn into kinetic energy,that means balance 55~60% energy is converted into heat,this heat may cause aging to motor components,which is harm to the motor life.DC brushless motor efficiency is always more than 80~95%,so only little energy changes to heat to prevent motor aging.

(3)Fast cooling/heating,temperature fluctuation is small,more comfortable.

a. If temperature difference between room temperature and setting temperature is big:

for normal AC style FCU,the fan will run under the setting speed;while the DC style will automatically run at high speed to make the room temperature to the setting temperature.

b. When the room temperature reach the setting temperature,the AC style fan coil will stop the fan running or close the water valve,this will cause the cooling/heating can not continue and there is temperature shock in the room;while the DC style fan coil will change its running speed according to the temperature difference between room temperature and setting temperature:if the distance is big, the fan speed will be higher,and if the distance is smaller ,the fan speed will be lower.

4. Eurostars Fan coil unit series

| 1 | Ceiling concealed fan coil unit |

| 2 | High ESP ducted fan coil unit |

| 3 | Universal concealed fan coil unit |

| 4 | Floor standing exposed fan coil unit |

| 5 | Ultra thin exposed fan coil unit |

| 6 | Ceiling exposed fan coil unit |

| 7 | Ceiling cassette fan coil unit |

| 8 | Ceiling exposed & floor standing fan coil unit |

| 9 | Wall mounted fan coil unit |

5. Ceiling floor standing exposed fan coil unit specification (DC motor)

Please ask salesman for detailed complete data or visit our website:

eurostarschiller.en.made-in-china.com

eurostarschiller.en.made-in-china.com

| Universal Exposed Fan Coil Unit(2 pipe system) | |||||||||||||

| Model EST | 200HE2 | 300HE2 | 400HE2 | 500HE2 | 600HE2 | 800HE2 | 1000HE2 | 1200HE2 | 1400HE2 | ||||

| 200VE2 | 300VE2 | 400VE2 | 500VE2 | 600VE2 | 800VE2 | 1000VE2 | 1200VE2 | 1400VE2 | |||||

| Power supply | 220V/1PH/50HZ | ||||||||||||

| Air flow (m3/h) | H | 340 | 510 | 680 | 850 | 1020 | 1360 | 1700 | 2040 | 2380 | |||

| M | / | / | / | / | / | / | / | / | / | ||||

| L | 120 | 160 | 220 | 270 | 330 | 420 | 570 | 670 | 760 | ||||

| Cooling capacity | TH | H | W | 1800 | 2700 | 3600 | 4500 | 5400 | 7200 | 9000 | 10800 | 12600 | |

| SH | W | 1368 | 2052 | 2736 | 3420 | 4103 | 5471 | 6839 | 8207 | 9575 | |||

| TH | M | W | / | / | / | / | / | / | / | / | / | ||

| SH | W | / | / | / | / | / | / | / | / | / | |||

| TH | L | W | 826 | 1101 | 1514 | 1858 | 2271 | 2891 | 3923 | 4611 | 5231 | ||

| SH | W | 516 | 688 | 946 | 1161 | 1419 | 1807 | 2452 | 2882 | 3269 | |||

| Heating capacity | H | W | 2700 | 4050 | 5400 | 6750 | 8100 | 10800 | 13500 | 16200 | 18900 | ||

| M | W | / | / | / | / | / | / | / | / | / | |||

| L | W | 1239 | 1652 | 2271 | 2787 | 3407 | 4336 | 5884 | 6917 | 7846 | |||

| Universal Exposed Fan Coil Unit(4 pipe system) | |||||||||||||

| Model EST | 200HE4 | 300HE4 | 400HE4 | 500HE4 | 600HE4 | 800HE4 | 1000HE4 | 1200HE4 | 1400HE4 | ||||

| 200VE4 | 300VE4 | 400VE4 | 500VE4 | 600VE4 | 800VE4 | 1000VE4 | 1200VE4 | 1400VE4 | |||||

| Power supply | 220V/1PH/50HZ | ||||||||||||

| Air flow (m3/h) | MAX | 340 | 510 | 680 | 850 | 1020 | 1360 | 1700 | 2040 | 2380 | |||

| / | / | / | / | / | / | / | / | / | / | ||||

| MIN | 120 | 160 | 220 | 270 | 330 | 420 | 570 | 670 | 760 | ||||

| Cooling capacity | TH | H | W | 1800 | 2700 | 3600 | 4500 | 5400 | 7200 | 9000 | 10800 | 12600 | |

| SH | W | 1368 | 2052 | 2736 | 3420 | 4103 | 5471 | 6839 | 8207 | 9575 | |||

| / | / | / | / | / | / | / | / | / | / | / | / | ||

| / | / | / | / | / | / | / | / | / | / | / | |||

| TH | L | W | 826 | 1101 | 1514 | 1858 | 2271 | 2891 | 3923 | 4611 | 5231 | ||

| SH | W | 516 | 688 | 946 | 1161 | 1419 | 1807 | 2452 | 2882 | 3269 | |||

| Heating capacity | MAX | W | 1300 | 1940 | 2590 | 3240 | 3890 | 5180 | 6480 | 7780 | 9070 | ||

| / | / | / | / | / | / | / | / | / | / | / | |||

| MIN | W | 596 | 791 | 1089 | 1338 | 1636 | 2080 | 2825 | 3322 | 3765 | |||

Remarks:

(1) Cooling: Inlet air temperature DB 27ºC,WB 19.5ºC; Chilled water inlet/outlet temp. 7ºC/12ºC.

(2) Heating: Inlet air temperature DB 20°C, heating water inlet/outlet temperature 60°C/50ºC.

6.Why choose EUROSTARS?

(1)With more certificate(2) Professional team with over more than 10 years industry knowledge

(3) Oversea installation.

(4) Customer-made accepted.

(5) Diamond member of Made-In-China

(6) Audited supplier by SGS

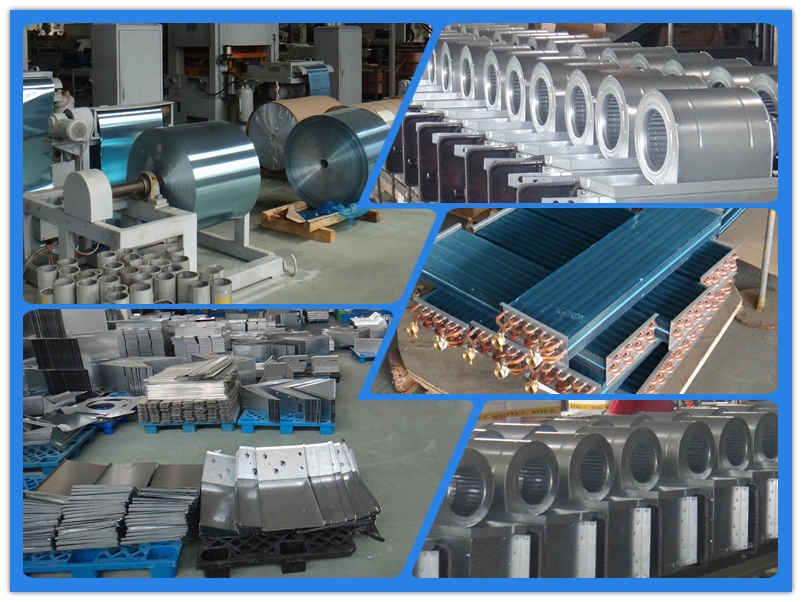

7. Our fan coil production line

Every fan coil has strict production process, including assembly, testing, packing.

8. Our service and Customer visit

Economical and energy-saving design scheme

Overseas engineer services

Integrated quality and profession R&D team

OEM/ODM available

9. Fan coil unit package and delivery

For bulk order, our standard package is carton packing for fan coil, for safe delivery and easy to load/unload, we will stack several layers together with plastic film and packing straps tightly onto the plywood or plastic pallets.

For sample order, we generally use plywood box or honeycomb cardboard to protect.

10. Fan coil unit projects

We exported fan coils to Serbia, Romania, Greece, France, South Africa, Australia, Uzbekistan, Mexico, Argentina, etc..

For bulk order, our standard package is carton packing for fan coil, for safe delivery and easy to load/unload, we will stack several layers together with plastic film and packing straps tightly onto the plywood or plastic pallets.

For sample order, we generally use plywood box or honeycomb cardboard to protect.

10. Fan coil unit projects

We exported fan coils to Serbia, Romania, Greece, France, South Africa, Australia, Uzbekistan, Mexico, Argentina, etc..